The 11th Class Date Sheet Sahiwal Board 2025 has been officially released. Students preparing for the BISE Sahiwal 1st Year Exams 2025 can now check their exam schedule. This date sheet applies to both regular and private students of Science and Arts groups. It is essential to follow the schedule and prepare accordingly to secure good marks in the exams.

The Sahiwal Board 11th Class Date Sheet 2025 provides students with a clear timeline of their upcoming exams. Knowing the exam dates in advance helps students effectively plan their study routine and revision strategies.

Table of Contents

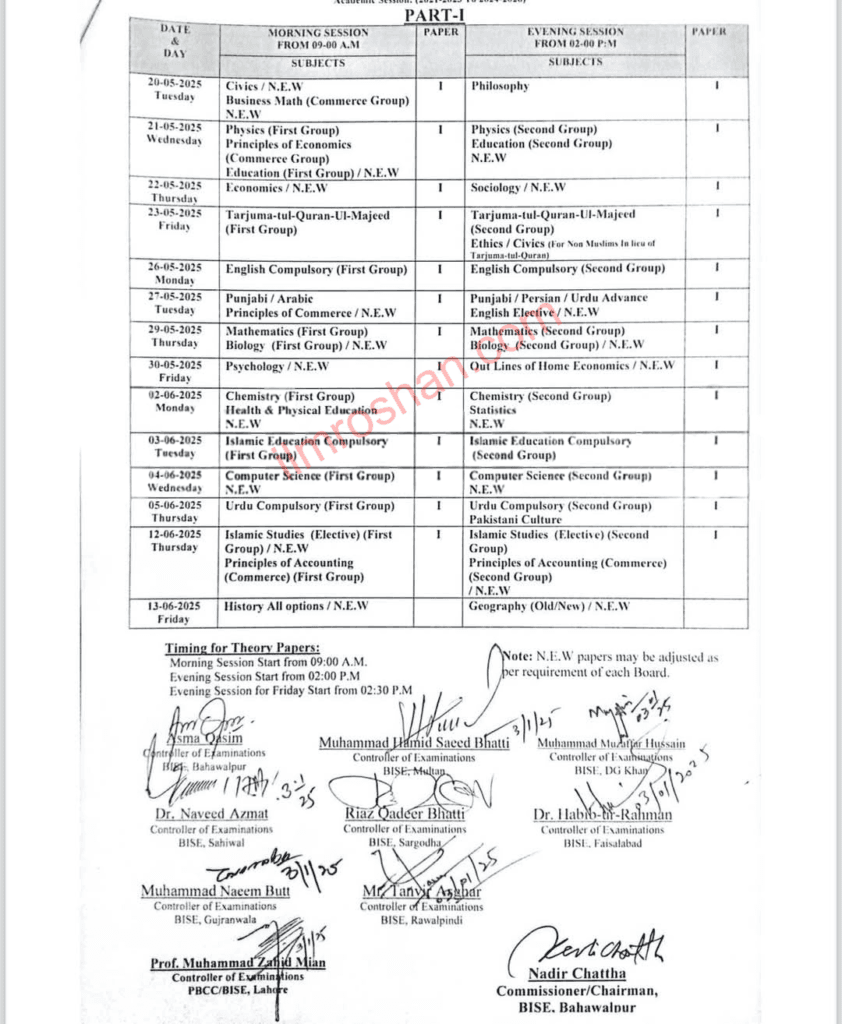

BISE Sahiwal 1st Year Date Sheet 2025 Overview

The 1st Year Date Sheet 2025 Sahiwal Board is now available for all students. Below are the important details regarding the exam schedule:

| BISE Sahiwal 1st Year Date Sheet 2025 Overview | |

|---|---|

| Board Name | BISE Sahiwal |

| Class | 11th Class (1st Year) |

| Date Sheet Release Date | March 2025 |

| Exam Start Date | May 20, 2025 |

| Last Exam Date | June 13, 2025 |

| Exam Timing (Morning Session) | 9:00 AM |

| Exam Timing (Evening Session) | 2:00 PM (Friday: 2:30 PM) |

| Posted By | IlmRoshan.com |

11th Class Date Sheet 2025 Sahiwal Board

| Date | Morning Session (9:00 AM) | Evening Session (2:00 PM) |

|---|---|---|

| 20-05-2025 (Tuesday) | Civics / Business Math (Commerce Group) | Philosophy |

| 21-05-2025 (Wednesday) | Physics (First Group), Principles of Economics (Commerce Group) | Physics (Second Group), Education (Second Group) |

| 22-05-2025 (Thursday) | Economics | Sociology |

| 23-05-2025 (Friday) | Tarjuma-tul-Quran-ul-Majeed | Tarjuma-tul-Quran-ul-Majeed (Second Group), Ethics (For Non-Muslims) |

| 26-05-2025 (Monday) | English Compulsory (First Group) | English Compulsory (Second Group) |

| 27-05-2025 (Tuesday) | Punjabi / Arabic, Principles of Commerce | Punjabi / Persian / Urdu Advance, English Elective |

| 29-05-2025 (Thursday) | Mathematics (First Group), Biology (First Group) | Mathematics (Second Group), Biology (Second Group) |

| 30-05-2025 (Friday) | Psychology | Outlines of Home Economics |

| 02-06-2025 (Monday) | Chemistry (First Group), Health & Physical Education | Chemistry (Second Group), Statistics |

| 03-06-2025 (Tuesday) | Islamic Education Compulsory | Islamic Education Compulsory (Second Group) |

| 04-06-2025 (Wednesday) | Computer Science (First Group) | Computer Science (Second Group) |

| 05-06-2025 (Thursday) | Urdu Compulsory (First Group) | Urdu Compulsory (Second Group), Pakistani Culture |

| 12-06-2025 (Thursday) | Islamic Studies (Elective), Principles of Accounting (Commerce) | Islamic Studies (Elective), Principles of Accounting (Commerce) |

| 13-06-2025 (Friday) | History (All Options) | Geography (Old/New) |

Official Date Sheet Image

About BISE Sahiwal Board

The Board of Intermediate and Secondary Education (BISE) Sahiwal was established to regulate and conduct exams for Matric and Intermediate levels. The board ensures transparency and efficiency in the examination system. Thousands of students from Sahiwal, Okara, and Vehari districts appear for exams under BISE Sahiwal every year.

The 1st Year Date Sheet 2025 Sahiwal Board is a crucial document for students. It helps them manage their time efficiently and prepare thoroughly for exams. Students are advised to follow the official schedule and stay updated through the BISE Sahiwal website for any further notifications.

For more updates, keep visiting Ilm Roshan!

How to Download 11th Class Date Sheet Sahiwal Board

The Class 11 Exam Date Sheet 2025 is easily available for Sahiwal Board students to download on the ILM Roshan website.

Check out ilmroshan.com.

Select the date sheets from the menu.

Choose the 11th Class and Boards.

Check the download link.

To get the date sheets, click the provided link.

Hi, ILM Roshan Team Here!

ILM Roshan Institute is a trusted educational platform dedicated to providing high-quality exam preparation materials, job updates, scholarships, and digital learning resources. Our mission is to empower students and professionals with the knowledge and tools needed for academic and career success.

🚀 Learn, Grow & Shine with ILMRoshan.com! 📚✨

electric motor balancing

Electric motor balancing is an essential process for ensuring the smooth operation of electric motors and other rotating equipment. Understanding the principles of rotor balancing helps in addressing issues related to vibration, wear, and efficiency. A rotor, which is a rotating body, requires proper mass distribution around its axis of rotation for optimal performance. When a rotor is perfectly balanced, any centrifugal forces acting on it are countered equally by opposing forces from symmetrically placed elements. This equilibrium leads to minimal vibration, extending the lifespan of the motor’s bearings and associated components.

However, when there is an imbalance—typically caused by asymmetrical mass distribution—the result is an uneven centrifugal force that generates vibrations. This imbalance can lead to increased wear on bearings, misalignment, and ultimately, equipment failure. Imbalances can be static, occurring when a rotor is at rest, or dynamic, which only manifests when the rotor is in motion. Dynamic imbalances are more complex as they involve centrifugal forces acting on unequal masses located in different planes of the rotor. Therefore, it’s vital to address both types of imbalance to ensure the effective operation of electric motors and other machinery.

Different types of rotors exhibit varying behaviors under centrifugal forces. Rigid rotors show minimal deformation, allowing for easier balancing. In contrast, flexible rotors require careful consideration of their dynamic characteristics since their deformation can complicate the balancing process. As speeds increase, some rotors may transition from behaving as rigid bodies to flexing, further complicating balancing efforts.

The imbalance must be corrected by either redistributing the rotor’s mass or adding compensating weights. Determining the correct size and placement of these weights is crucial. For effective balancing, one must identify not just the presence of an unbalance but also its nature—static or dynamic. Static unbalances are addressed by correcting the positioning of masses without needing the rotor to rotate, while dynamic unbalances require precision handling during operation.

To achieve proper electric motor balancing, various methods can be employed. The process typically involves the use of specialized balancing equipment, such as balancers and vibration analyzers. These devices help measure vibration levels in real-time, analyze the rotor’s response to known weights, and calculate the necessary compensating weights to restore balance. The balancing process is both an art and a science, requiring an understanding of vibration theory, mechanical properties, and practical experience.

Vibration analysis plays a significant role in rotor balancing. Various types of sensors, including accelerometers, are utilized to gather data on vibrating surfaces. This data allows for the assessment of vibrations caused not only by unbalances but also by other factors like misalignment and structural integrity issues forced by manufacturing errors. Accurate vibration analysis thus aids in identifying and differentiating between various causes of vibration, ensuring that proper remedial actions can be taken.

The balancing of electric motors often follows established industry standards and guidelines to ensure consistent quality. Standards such as ISO 1940-1 detail permissible imbalance levels and methods for evaluating balance quality based on type and size of rotors. These criteria help manufacturers and maintenance personnel maintain equipment reliability and efficiency, essential for the smooth operation of industries reliant on electric motors.

Furthermore, special considerations apply when dealing with balancing in resonance conditions. As the rotor speed approaches its natural vibration frequency, resonance may occur, potentially resulting in catastrophic failures. Procedures for balancing in such scenarios require expert knowledge and often involve unique balance approaches that go beyond standard practices.

Thus, the balancing of electric motors is a multi-faceted process that involves understanding rotational dynamics, utilizing advanced measurement techniques, and adhering to strict standards. The interplay of rigid and flexible rotor characteristics, types of imbalance, and vibrational responses necessitates a comprehensive approach that incorporates theory with practical application. Without proper balancing, electric motors can suffer from reduced efficiency, increased operational costs, and premature failures, making it crucial for operators and technicians to effectively manage this aspect of motor maintenance.

Overall, electric motor balancing is a critical aspect of motor performance, impacting everything from efficiency to longevity. It’s a vital maintenance practice that can save industries time and resources by preventing breakdowns and ensuring operational reliability. Understanding the principles and techniques behind rotor balancing is essential for anyone involved in the field of mechanical engineering, maintenance, or manufacturing to ensure they can implement effective solutions for their rotating machinery.